Company

Introduction

Innovation that sets the foundation apart,

a Lifestyle Facilitator in the textile and

trading industry

R&D

-

R&D

The Hyosung Technical Institute was established in 1971 as the first private enterprise-affiliated research institute in South Korea, and in the 1970s, it developed research and technological capabilities in the field of synthetic fibers, which became the driving force behind the country's economic growth.

Based on this, we expanded our research areas to chemical materials, products, and new materials. The Textile Research Group at the Hyosung Technical Institute, with its accumulated expertise in fibers such as polymerization, spinning, drawing, and post-processing, leads high value-added fiber technology in Spandex, nylon, polyester yarn, and more, focusing on developing new products and new processes and commercializing them to enhance the lives of everyone.

In addition, sustainable material development, a core direction of our R&D, is pursued through innovative sustainable technologies, including the world's first recycling of discarded fishing nets into nylon and the world's first bio-based Spandex, contributing to sustainable fiber material research for the future of every generation.

Research areas

Functional

Fiber Materials

FUNCTIONAL FIBER

Sustainable

Fiber Materials

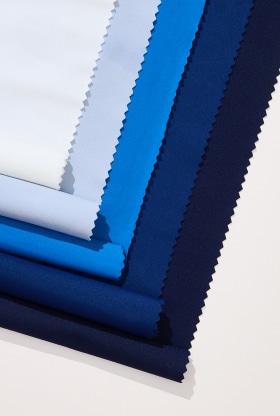

- Spandex

- Nylon

- Polyester

SUSTAINABLE FIBER

Hyosung TNC strives to develop and commercialize new products and processes.

-

Major Development Milestones